Smart Grader Evo

EFFECTIVE AND PRODUCT FRIENDLY

The Smart Grader EVO is mainly used for grading potatoes, but is also perfectly suitable for shallots, onions and sweet potatoes.

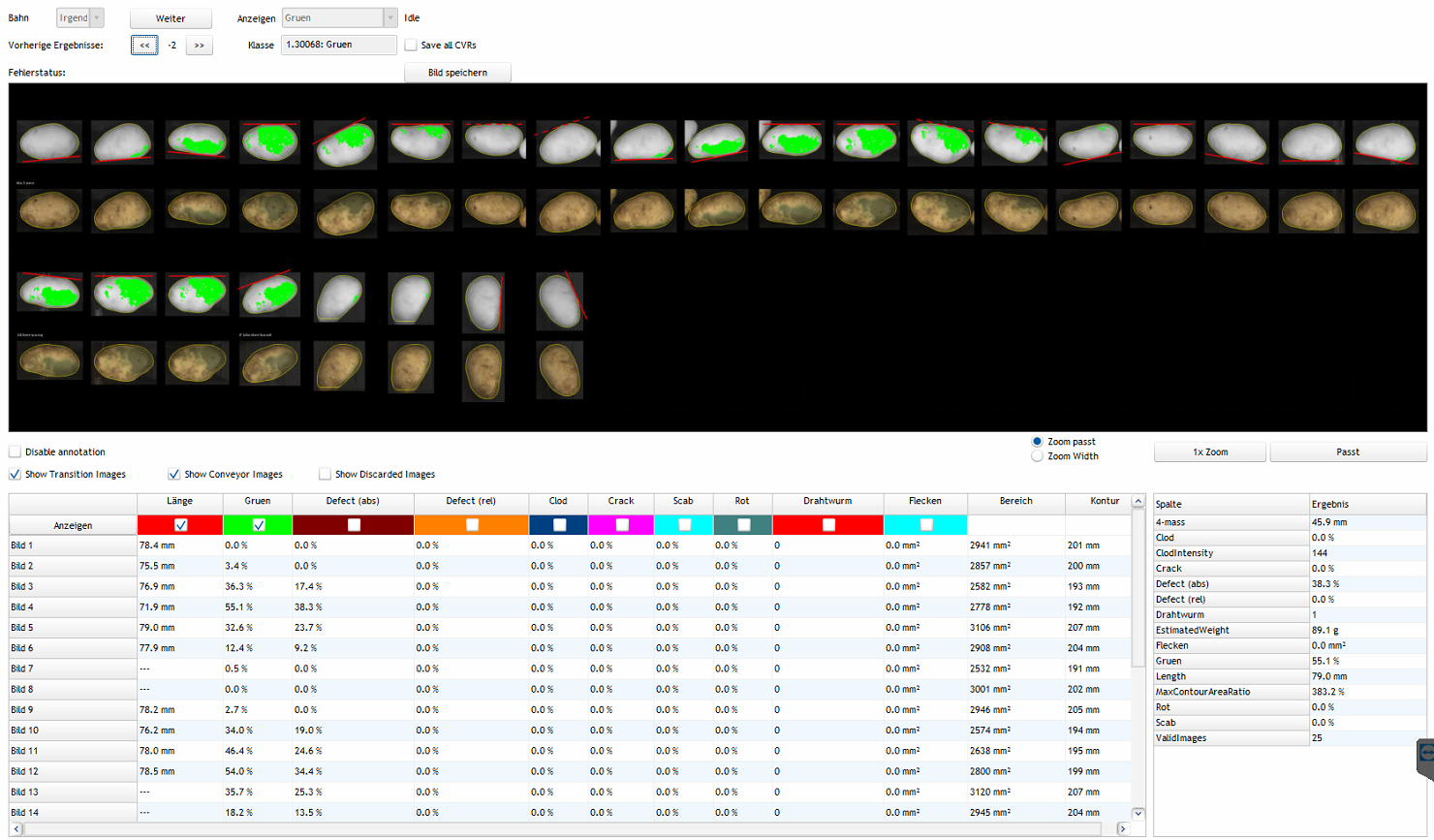

The product stream is divided on a vibrating unit, which causes the product to pass individually over the rollers. Thanks to the rolling motion, each product is accurately assessed by the high-resolution cameras, whose criteria can be easily set.

Even wire worms, scab and bump marks are recognized flawlessly. Depending on the shape or quality characteristics, the products are conveyed to correct exit of the belt; very effective and product-friendly.

Modular expandable

The Smart Grader EVO is available with two, four, eight or 12 lanes. Each type of Smart Grader EVO can be easily linked together. This modular option makes it possible to increase capacity.

Customized advice?

24/7 THE SAME PRECISION

The Smart Grader EVO sorts more accurately than the human eye, is tireless and operates 24/7 with the same precision.

Plus, all grading info is stored on a lot-by-lot basis, so you know exactly what you are delivering and the buyer knows exactly what they are receiving.

GeJo provides total solutions!

GeJo Grading develops custom grading solutions. Grading installations are designed in close consultation with the client and tailored to the circumstances. If required, we also involve fellow machine builders to ensure that all components are correctly matched and the optimum capacity can be achieved.

Ultimately, all links within the sorting process contribute to the success of your sorting line! And we like to think along with you about that.

Customized advice?

The facts in a row

- Size and quality

- Running autonomously

- 1 ton/h per job at an average tuber weight of 100 grams

- Lanes/exits modular

- Data insightful

- Return on investment demonstrable

USER EXPERIENCES

Find out what customers are saying about our Smart Grader EVO in the user reviews below.

Smart Grader EVO 408 Kartoffelhof Meyer DE

Torsten Meyer has been working with the Smart Grader 408 for 2 years now. He talks about his experiences.

Smart Grader EVO 208 Kartoffelhof Hölck DE

Een Smart Grader EVO 208 draait met een bunker van Bijlsma Hercules bij Kartoffelhof Hölck in Reinsbüttel. Lennart en Thorsten vertellen over hun ervaringen!

Smart Grader READER 3.0 Jensma testimonial NL

Klaas Jan Jensma is a seed potato grower and he has been using the Smart Grader Reader for 3 years to determine the right time to kill the haulm. That process starts with very regular trial harvesting on all his plots.

Smart Grader EVO 808 at Fimm’s in Scotland

FIMM Potatoes, Muthill – Perthshire – UK FIMM delivers seed potatoes of the very highest quality using a Smart Grader EVO 808. It is a leap forward in grading quality and saves an enormous amount of labor.

Smart Grader EVO 208 bij Brasseler in Viersen (D)

Brasseler, Vierssen – D Boris Brasseler sorts with his Smart Grader EVO 208 about 1000 – 1500 tons of consumption potatoes annually, which he sells in his own country store. He simply wants to provide the customer with the best quality and his Smart Grader makes an important contribution to that.

Mts. Reitsma-Hazelhoff, Ferwert – NL

Nantko Reitsma operates a Smart Grader EVO 408 with four lanes and eight exits. He is part of a custom-built grader, with six large bunkers and two independent unloading lines from Bijlsma Hercules.

Batati, Fräschels – CH

At Batati in Switzerland, the Smart Grader EVO 408 plays a leading role in their sweet potato washing, sorting and packaging line.

Kartoffelhof Ottensmeier, Bünde – D

Jobst Ottensmeier is enthusiastic about their Smart Grader EVO 206. He uses it daily to sort his Erdengold ware potatoes as well as onions, which are sold in his own country store and at supermarkets in the region.